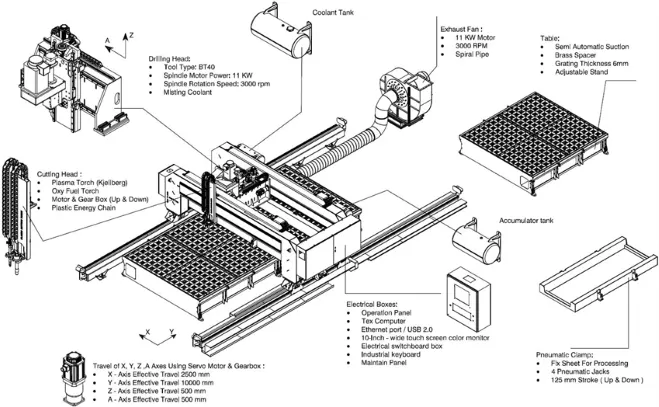

این دستگاه برای سوراخکاری ورق و انجام برشهای دقیق در اشکال و اندازههای مختلف با استفاده از تکنیکهای برش Oxy-Fuel و پلاسما طراحی شده است. امکانات و ویژگیهای منحصر به فرد این دستگاه باعث بهبود عملکرد و افزایش دقت در عملیات برش میشود.

ویژگیها و تجهیزات ماشین فرایند آماده سازی ورق کارا

2.یونیت اسپیندل سوراخکاری:

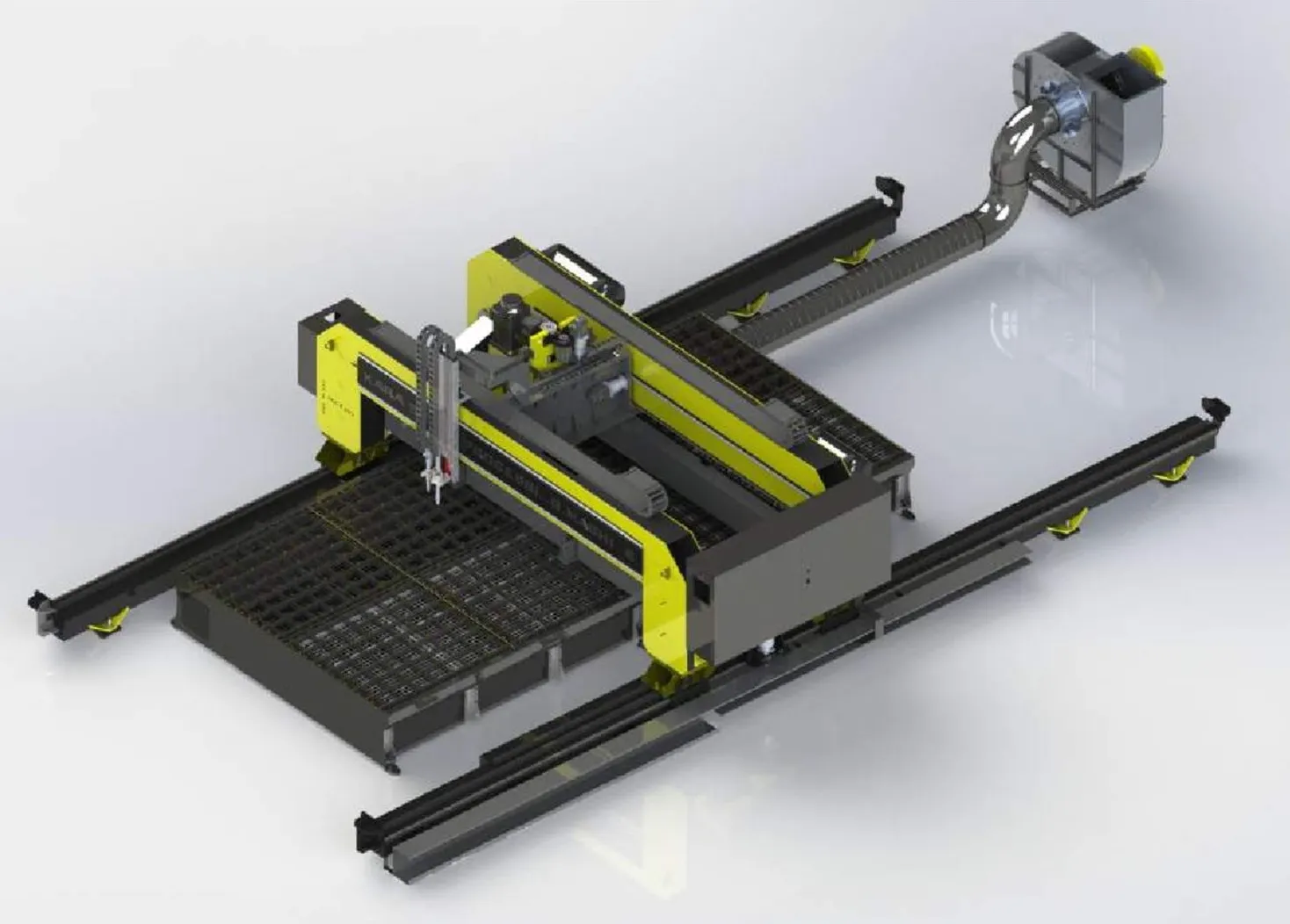

3. سیستم حرکتی:

4. سیستم کنترل و ایمنی:

5. ساختار مکانیکی:

6. سیستم پنوماتیک:

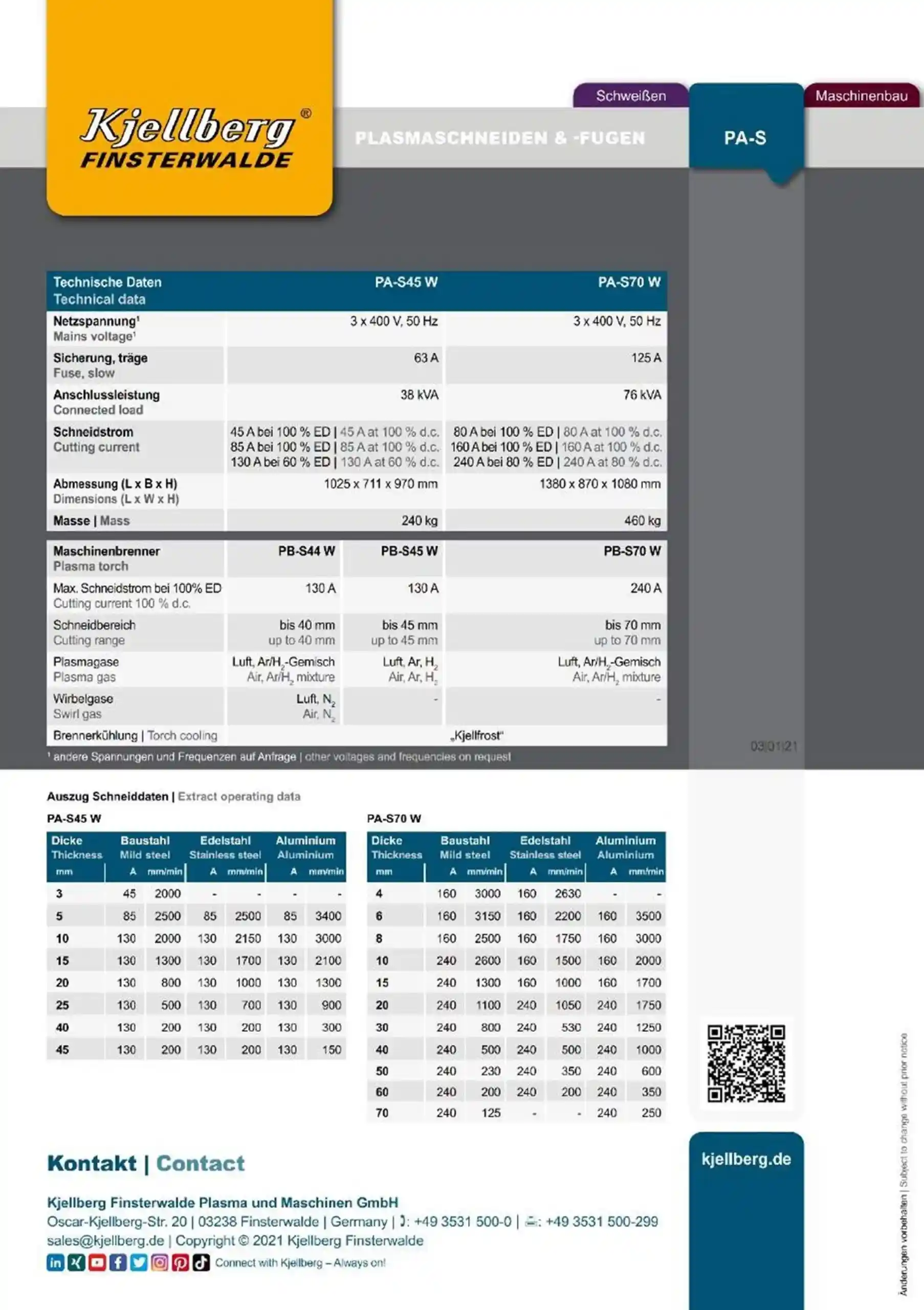

| description | subject |

|---|---|

| MAX = 6000 x 2500 | Sheet Length (mm) |

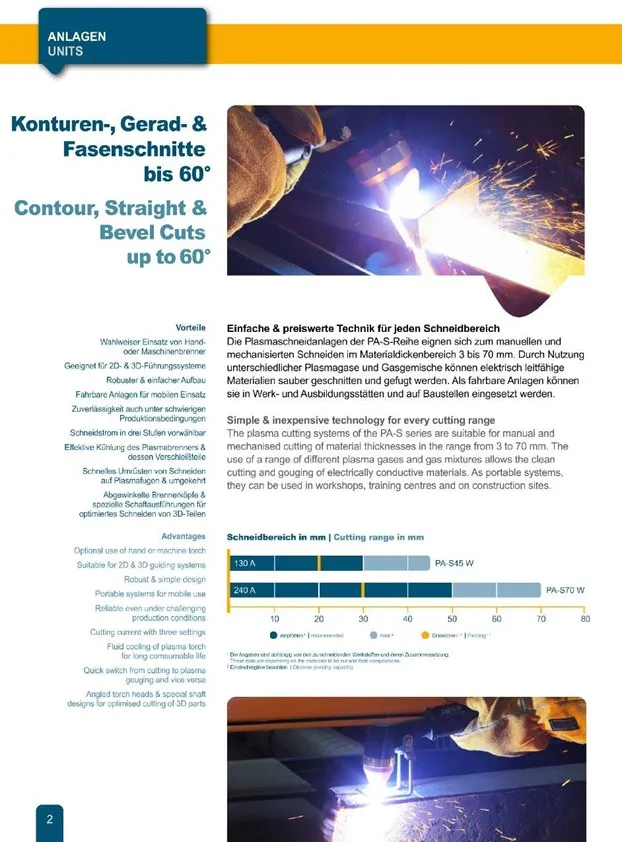

| Plasma & Oxy-fuel | cutting torches |

| Kjellberg PA-S70W | Plasma cutting’s power supply (by default) |

| UP to 70 mm | Plasma cutting thickness |

| Air, AR/2H2 Mixture | Plasma hole piercing thickness |

| Single Torch: 5 – 100 mm | Oxy-fuel cutting thickness |

| 6000 | Maximum jogging speed (mm/min) |

| Tex Computer (Itay) | Machine’s control system (optional) |

| Flashback Arrestor | Cutting Flame’s safety system |

| Automatic height control (base on arc voltage) Internal for Tex- Computer | Plasma torch adjustment system |

| IP 20 | Protection classification |

| 380V – 50Hz – 3PH – 63A | Machine’s Electric Power Consumption |

| Energy chain guide | Cable protection and guidance system |

| Automatic spark plug transformer | System for turning on oxy-fuel cutting torch |

| Automatic height control (capacitive) | Oxy-fuel torch’s height adjustment system |

| Linear & Cabin- Helical Rack & Pinion | Machine’s linear movement system |

| Servo motors + planetary gearbox | Machine’s Driving components |

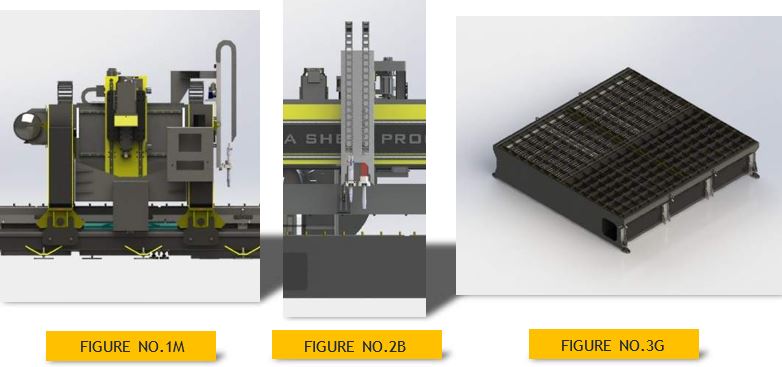

| 1,000,052,003,000 | Overall Machine’s Dimension (mm) (L, H, W) |

| 12000 | Overall Machine’s Weight (kg) |

| description | subject |

|---|---|

| Length: 6000 mm, Width: 2500 mm, Thickness: 8 – 70 mm | Effective workpiece dimensions |

| 1 Spindle – BT 40 | Number of spindles |

| 3 Axis | Number of machine axis |

| AC Servo Motor: 11 kw Max Spindle Speed: 3000 Rpm | Specifications and speed range of the spindle |

| Tex Computer (ITALY) | Machine’s control system |

| G Code Generation (External Software) – USB | Machine’s Control system features |

| 6000 mm/min | Maximum linear velocity of Y axis (Longitudinal movement of the gate) |

| 6000 mm/min | Maximum X-axis linear velocity (Transverse spindle motion) |

| 5000 mm/min | Maximum Z axis linear velocity (Vertical spindle motion) |

| 650 mm | Z-axis motion course (vertical spindle motion) |

| ± 0.02 mm | Machine’s Movement accuracy |

| Depended to drill life and quality | Machine’s Drilling accuracy |

| HSS: Min: 6 mm / Max: 35 mm (direct) HSS: Max 40 mm (with leading drill) Drill insert (spade drill) HSS Min: 10 mm / Max: 35 mm Index-able U-Drill: Min 24mm / Max 30 mm | Type of drills |

| Horizontal Disc Type Magazine / Capacity: 3 Tools Tool Model: BT 40 / Max Tool Length: 320 mm | Tool change magazine (Optional) |

| 4 Jacks | Pneumatic Clamp |

| Misting Coolant, Internal & External | Coolant system |

| AC Servo Motor: 2x (3Kw – 1000 rpm) Rack & Pinion + Linear Guide | Y-axis motor and gearbox (Longitudinal movement of the gate) |

| AC Servo Motor: 1.5 Kw – 1000 rpm Rack & Pinion + Linear Guide | X-axis motor and gearbox (Spindle transverse motion) |

| AC Servo Motor: 1.5 Kw – 2000 rpm Electrical Break Pulley and Timing Belt / Ball Screw + Linear Guide | Z-axis motor and gearbox |

| IP 20 | Panel’s degree of protection |

| Nominal Current @ max. load = 380 V – 50 Hz – 3 Ph-35 A | Machine’s Electric Power Consumption (full load) |

| Coolant Sprinkler Guns/ compressed air: Blower Guns z | Operator’s application equipment |

| description | subject |

|---|---|

| Length: 6000 mm, Width: 2500 mm, Thickness: 8 – 70 mm | Effective workpiece dimensions |

| Length:3200 mm, Width :3050 mm, height: 720 mm | Overall table dimensions of each Table |

| 3 pieces at a distance of 1 meter | Proximity sensor of each Table |

| 3 pieces at a distance of 1 meter | Pneumatic jack |

| 11 Kw, 3000 RPM | Exhaust fan |

| 512 pieces | Brass Spacer |

| Spiral type | Canal |