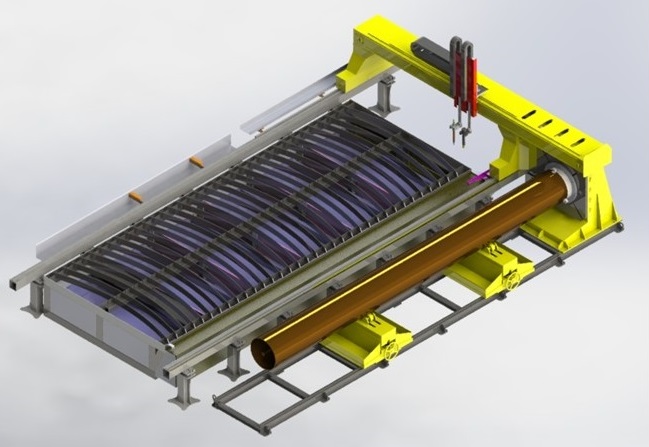

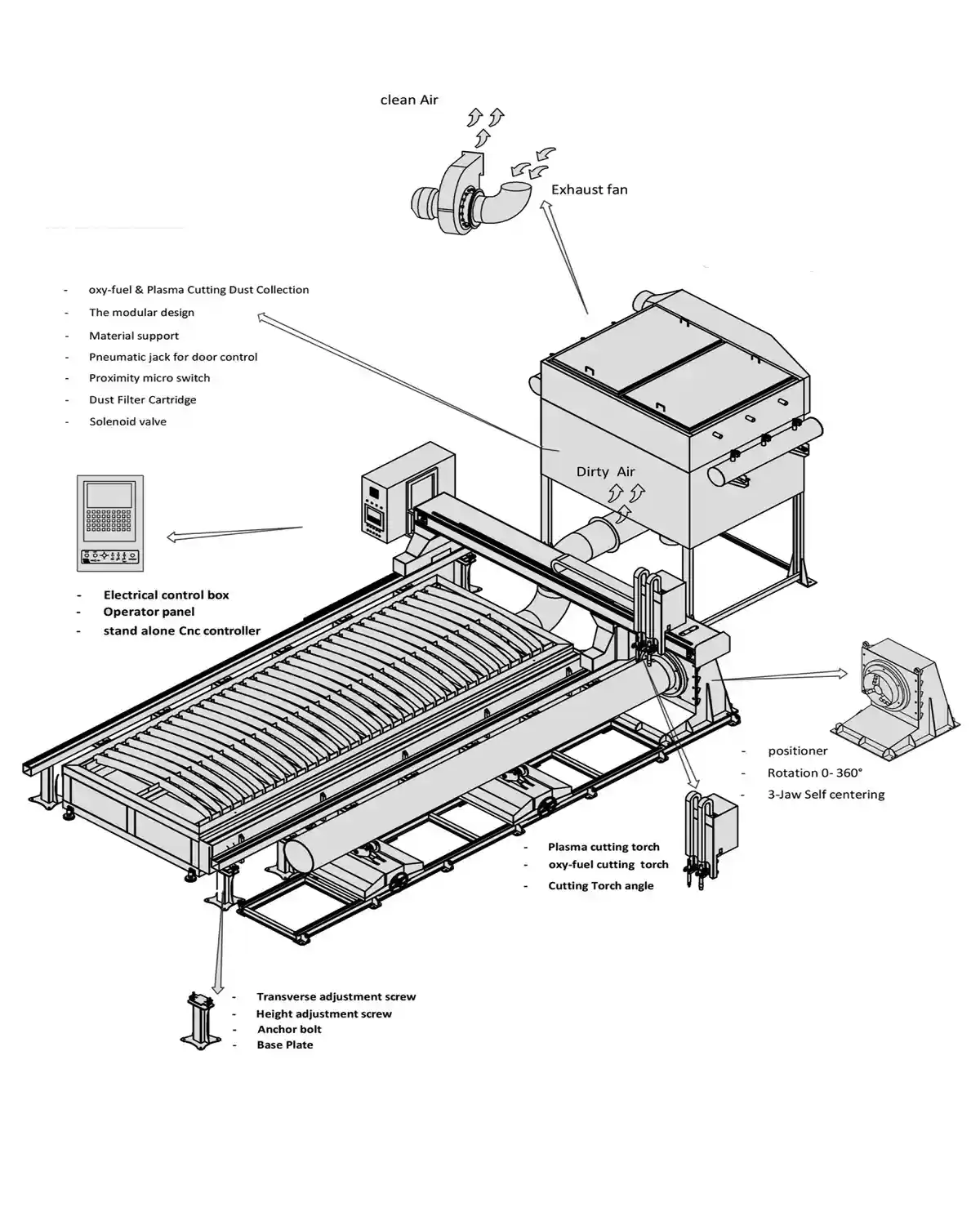

دستگاه CNC برش ورق و لوله کارا به گونهای طراحی شده است که برشهای دقیق را در اشکال و اندازههای مختلف با استفاده از تکنیکهای برش پلاسما انجام میدهد. این دستگاه با ویژگیهای زیر، کارایی و دقت بالایی را ارائه میدهد:

دستگاه CNC برش ورق و لوله کارا به دلیل ساختار قوی و تجهیزات پیشرفته، انتخابی ایدهآل برای انجام برشهای دقیق و با کیفیت بالا در صنایع مختلف است.

دستگاه جوش پلاسما 200 آمپر کارا

| Descriptions | Subject |

|---|---|

| 2500 | Effective cutting width (mm) |

| 6000 | Effective cutting length (mm) |

| Single: Plasma OR Oxy-fuel Compact: Plasma & Oxy-fuel Master-Slave: Main Oxy-fuel Drive Station & Slave stations | Number of cutting stations |

| KARA Plasma 200 A | Plasma cutting’s power supply |

| 0.5 – 25 for Carbon steel 0.5 – 20 for Stainless Steel 0.5 – 15 for Aluminum | Plasma cutting thickness (mm) |

| Single Torch: 300 / Five Torches: 5 – 100 | Oxy-fuel cutting thickness (mm) |

| 7000 | Maximum Contour’s speed (mm/min) |

| TexComputer (Itay) | Machine’s control system (optional) |

| Flashback Arrestor | Cutting Flame’s Reflect Protection system |

| Automatic height control | Cutting Torch’s Protection system |

| IP 20 | Panel’s degree of protection |

| 220V-50 Hz-1PH-16A | Machine’s Electric Power Consumption |

| Energy chain guide | Cable protection and guidance system |

| Automatic spark plug transformer | System for turning on/off cutting torch |

| T90/B (T16) + Helical rack & pinion | Machine’s linear movement system |

| Servo motors + planetary gearbox | Machine’s Driving components |

| Width: Up to 4m Length: Up to 12 m | Possibility to increase the length and width of machine (optional) |

| 7900 x 5500 | Overall Machine’s Dimension (mm) |

| ≈ 3200 | Overall Machine’s Weight (kg) |

| Automatic plasma’s fume suction Mechanism | Machine’s Worktable Options |

| Descriptions | subjects |

|---|---|

| Ø50 mm – Ø500 mm | Working diameter (Min. & Max.) |

| Min: 100 mm / Max: 6000 mm | Pipe length (Min. & Max.) |

| 4000 | Pipe Maximum loading capacity (kg) |

| 3 Jaw Chuck -Ø500 mm | Pipe clamping system |

| Adjustable subsets according to Pipe diameter and length changes | Pipe retaining system along cutting path |

| Descriptions | Subject |

|---|---|

| Thyristor Control | Type of voltage control |

| Stepless | Current control steps |

| 25A/110v ~ 200A/200V | Current Voltage Range |

| 200A | Permissible Load @100% D.C. |

| 380V | Open Circuit Voltage |

| 100A | Input Fuse Slow |

| 100A | Input Current@ 100% D.C. |

| 66KW | Max Power |

| 500 kw | No Load power |

| 3×380 V/50Hz | Mains input power |

| Thermostat | Over Load Protection |

| IP20 | Protection Class |

| H | Insulation Class |

| 760/590/1435 mm | Dimension L/W/H |

| 460 Kg | Weight |

| 7 Bars | Air Input Pressure |

| 230 L/min | Air Consumption |

| A.F. | Cooling Type |

| 6 m (additional are available by request) | Torch Cable Length |