دستگاه دریل سی ان سی 10 محور کارا امکان سوراخکاری همزمان سه اسپیندل سوراخکاری را بر روی قطعه کار که می تواند تیر با مقطع اچ و یا تیر با مقطع مستطیلی باشد را فراهم میکند.

سیستم کنترل دستگاه دستگاه دریل سی ان سی 10 محور کارا

ویژگیهای فنی دستگاه دریل سی ان سی 10 محور کارا

| Descriptions | Subjects |

|---|---|

| Web: 200 – 1200 mm / Flange: 200 – 500 mm Length: 2500 – 12000 mm / Thickness: 10 – 50 mm | Effective workpiece dimensions |

| 3 Spindles | Number of spindles |

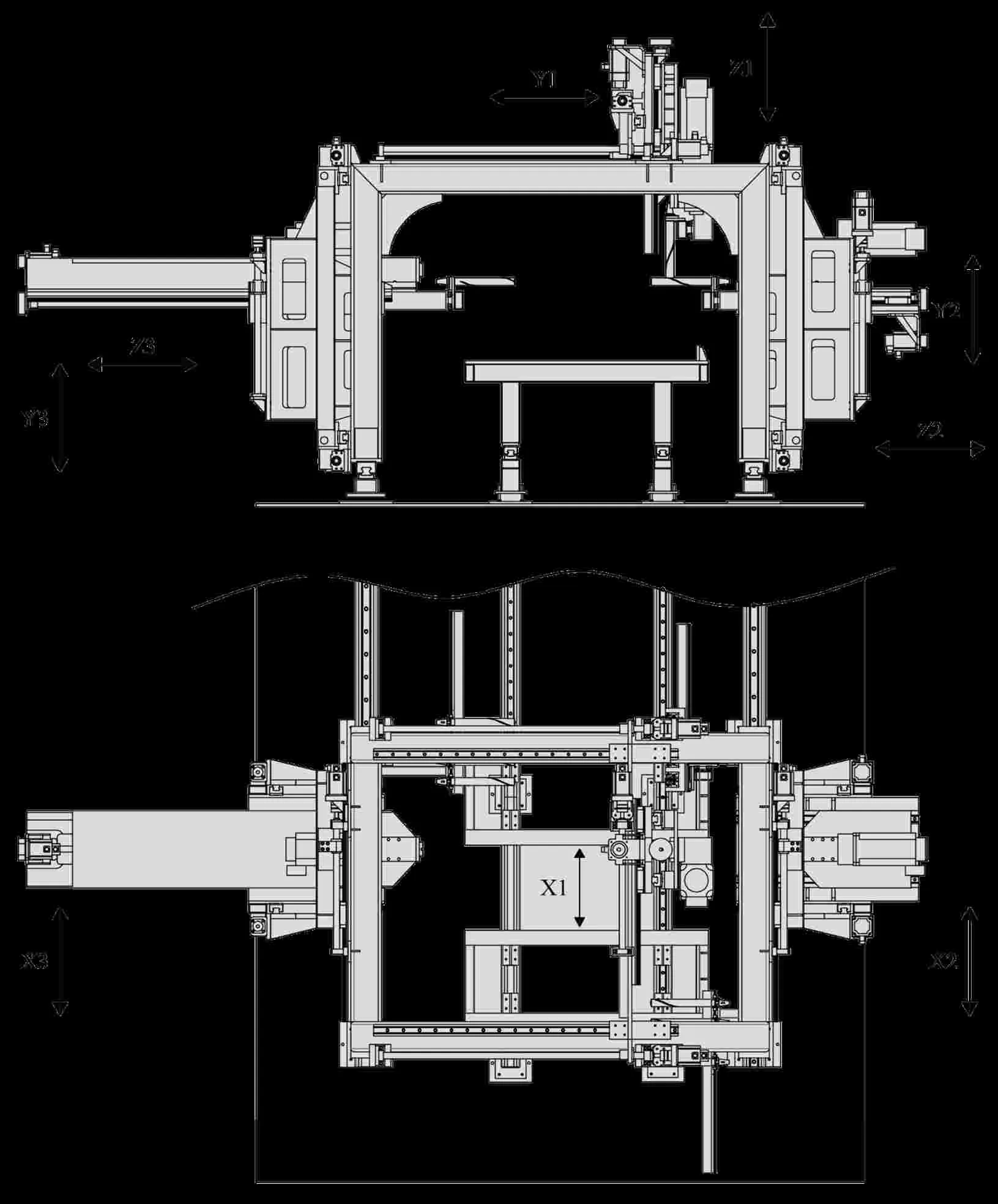

| 10 AXES | Number of machine axes |

| AC Servo Motor: 18 kw / Max Spindle Speed: 3500 rpm Max Drilling Torque: 230 Nm. / Spindle Taper: BT 40 | Specifications and speed range of the spindle |

| PC Base – Promax ITALY, under network servo control, 10 Axis Simultaneous, Flex 3D – for G code generator (Lintec – Spain) | Machine’s control system |

| Monitor: 17´ – Color – Touch Screen, USB, WIFI | Machine’s Control system features |

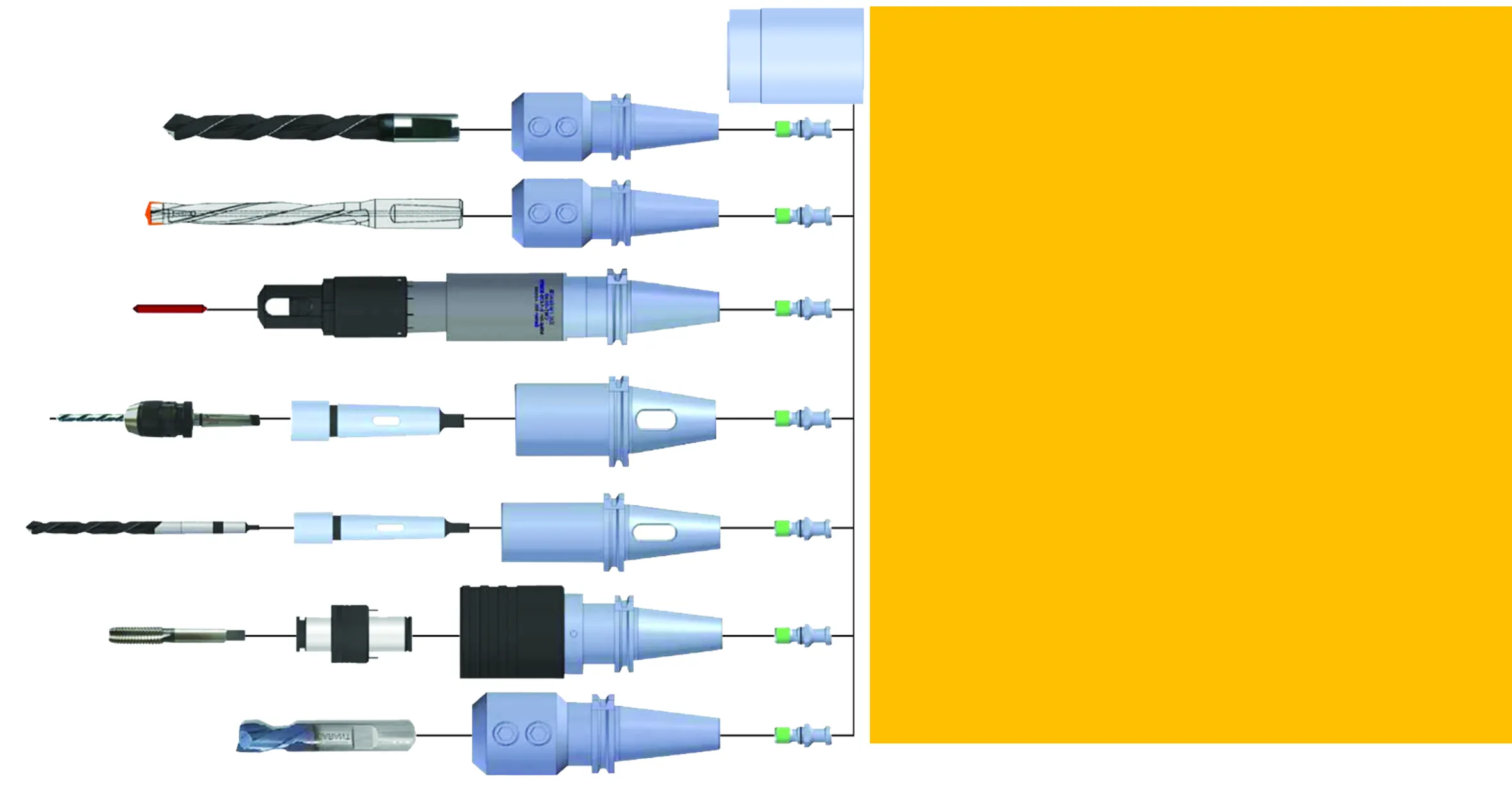

| Equipped with 3 magazines for each spindle Drilling, Milling | Tool replacement system |

| Linear Tool Change Magazine / Capacity: 4 Tools Tool Model: BT 40 / Max Tool Length: 320 mm | Tool replacement set |

| HSS: Max 35 mm (direct) HSS: Max 40 mm (with leading drill) Drill insert (spade drill) HSS: Max 24 mm | Type of drills |

| 6000 mm/min | Maximum linear velocity of Y axis (Transverse movement of spindle) |

| 6000 mm/min | Maximum X-axis linear velocity (Transverse spindle motion) |

| 6000 mm/min | Maximum linear velocity of Z axis (Spindle transverse motion) |

| 500 mm | Effective x-axis motion course in three spindles |

| ± 0.02 | Spindle movement accuracy |

| Depended to drill life and quality | Machine’s drilling accuracy |

| By optic sensor install on gantry | Workpiece referencing system |

| Misting Coolant – Internal & External B. Equipped with pneumatic automatic guidance system for welding torches under PLC control. C. Equipped with adjustment system and clamp to the flange of the sheet beam when starting the assembly. D. Equipped with hydraulic jack adjustment system to correct the deflection of the beam flange during assembly | Cooling system |

| 3X (CCD Camera) + 32” LCD TV | Monitoring |

| 2 vertical hydraulic clamps on the gate | Number of clamps holding the workpiece |

| AC Servo Motor: 3 Kw – 1000 rpm Low Backlash Gearbox Rack & Pinion + Linear Guide | Axis A motor and gearbox (Longitudinal movement of the workpiece) |

| AC Servo Motor: 2 x (1Kw – 1000 rpm) Direct Flexible Coupling Ball Screw + Linear Guide | Y-axis motor and gearbox (Transverse spindle movement) |

| AC Servo Motor: 2 x (1Kw – 1000 rpm) Direct Flexible Coupling Ball Screw + Linear Guide | X-axis motor and gearbox (Longitudinal movement of spindle) |

| AC Servo Motor: 1Kw – 1000 rpm Electrical Break Pulley and Timing Belt Ball Screw + Linear Guide | Z-axis motor and gearbox (Spindle forward motion) |

| IP52 | Panel’s degree of protection |

| Nominal Current @ max. load = 380 V – 50 Hz – 3 Ph – 90 A | Machine’s Electric Power Consumption |

| AC Motor 0.25 KW – 1400 rpm | Unit cooling system |

| L: 2400 mm, W: 7000 mm, H: 3200 mm | Overall Machine’s Dimension (mm) |

| 80700 kg | Overall Machine’s Weight (kg) |

| 12m | Infeed Conveyor Length |

| 12m | Outfeed Conveyor Length |

| 750 kg/m | Weight per Linear Meter |

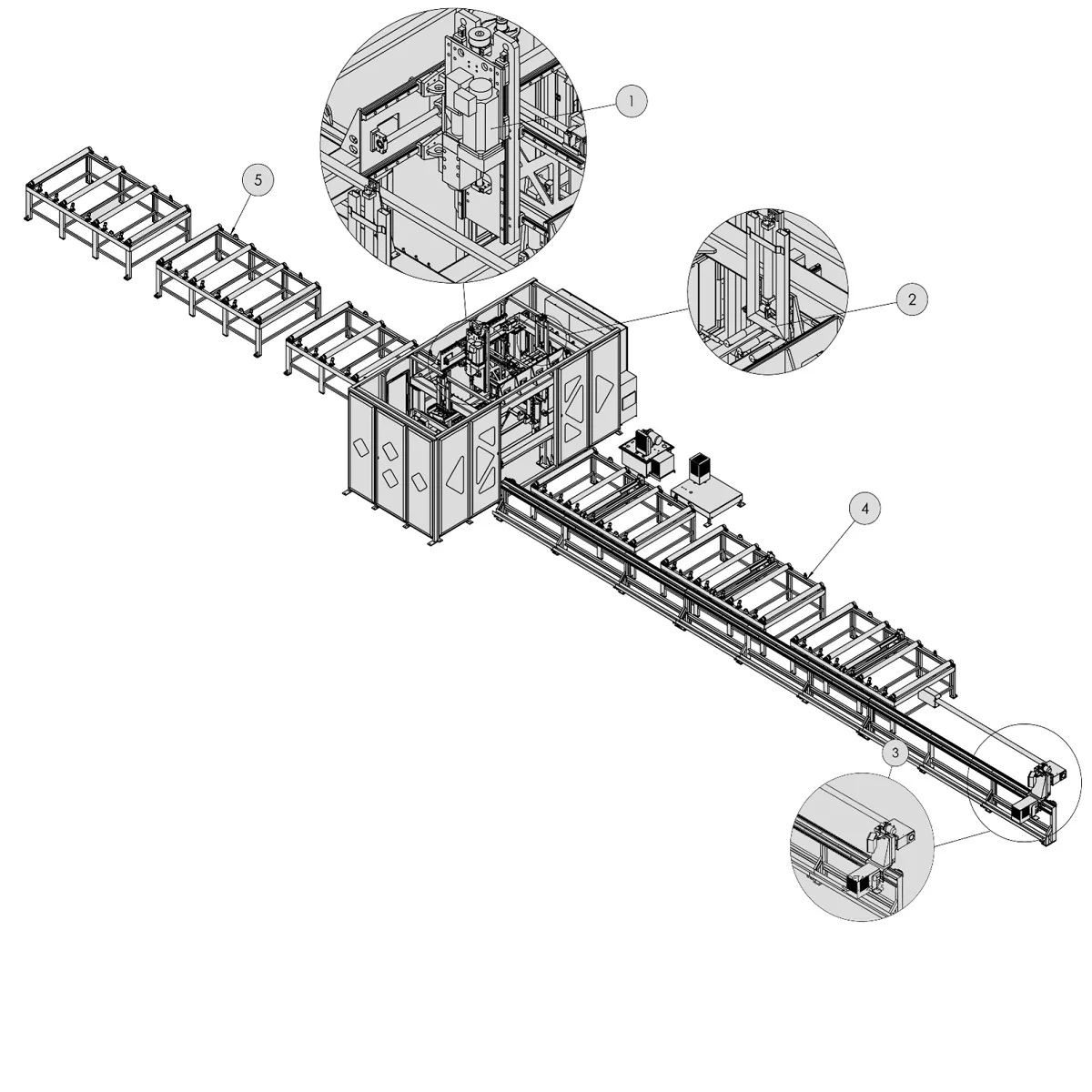

| No. | Item |

|---|---|

| 1 | Drilling Unit Spindle |

| 2 | Tools replacement System |

| 3 | Workpiece Pusher |

| 4 | Infeed Conveyor |

| 5 | Outfeed Conveyor |

| Subject | Descriptions |

|---|---|

| CPU | MFC 5441x Cold Fire 32 Bit 250 Mhz 410 Mips |

| RAM | 64 Mb ram – 64Mb flash code – 32 Kb ram clock with battery 64 Mb flash Disk |

| RS232/485 | 2 – RS232 1 /485 with MODBUS RTU master/slave |

| ETHERNET | 1 – RJ45 10-100 Mb: TCP/P – MDBUS TCP/IP – WEB SERVER – RPC (remote procedure call) – DEBUG |

| ETHERCAT | 1 – Master 100 Mb/sec CoE Can Over Ethercat |

| CANOPEN | 2 – Master/Slave DS301 – DS401 – DS402 baud from 10 Kb/sec up to 1 Mb/sec |

| INTERPOLATION | Linear – Circular – Elicoidal – Linear fast – Gear – Ecam – Interpolation ULTIPROCESS |

| AXES | Up to 16 +/- 10V with encoder (max 1 Mhz) up to 64 Can Open or Ethercat up to 32 STEP/DIR LINE DRIVE Freq max 25 MHZ |

| ANALOG INPUTS | 8 – 10-bit 4-20 Ma or 0-10V (all voltage with external resistor) |

| POWER SUPPLY | 18-35 Vdc – 2,6 W max ONLY CPU |

| TEMPERATURE | From -20ºC to 70ºC |

| IP LEVEL | IP20 |

| DIMENSION | W 30 H 190 D 110 (mm) |

| Subject | Descriptions |

|---|---|

| NGIO | 16 – Digital Input PNP 24 VDC Opto / 14 – Digital Out 24 VDC opto 1,2 A 2 – I encoder Input Line Drive 5 V freq Max 1 Mhz 2 – Analog Out +/- 10 V 12 bit 2 – Rele’ Out Max 35 V – 1 A |

| NGPP+ | 16 – Digital Input PNP 24 VDC Opto 14 – Digital Out 24 VDC opto 1,2 A 4 – Axes STEP/DIR line drive freq MAX 25 MHZ 4 – Fast interrupt Input 1 – Analog Out 0 – 10 V 12 bit |

| No. | Item |

|---|---|

| 1 | Drilling Unit Spindle |

| 2 | Tools replacement System |

| 3 | Workpiece Pusher |

| 4 | Infeed Conveyor |

| 5 | Outfeed Conveyor |